Technical Analysis and Application of Locking Assemblies Coupling in High-Speed, Heavy-Duty Drive Systems

In large industrial drive systems (e.g., gas turbine generator sets, marine propulsion systems, pipeline compressors), couplings are not merely components for transmitting torque and motion; they are the "bridge" connecting the prime mover to the driven machine. Their performance directly impacts the entire unit's safety, stability, and economy. Diaphragm couplings, renowned for their zero backlash, high torsional stiffness, lubrication-free operation, and ability to compensate for combined displacements, have become the preferred choice for such high-end applications.

However, traditional diaphragm couplings typically use flanged connections with through bolts, relying on the frictional force generated by the preload of circumferentially distributed high-strength bolts to transmit torque. This method has several inherent drawbacks:

Stress Concentration: Bolt holes weaken the flange strength and cause significant stress concentration.

Assembly Sensitivity: The uniformity of bolt preload drastically affects torque transmission capacity, requiring extremely high assembly precision.

Fretting Wear: Under alternating loads, fretting wear can occur between the bolts and hole walls, leading to connection loosening and potentially catastrophic failure.

The introduction of Locking Assemblies coupling technology fundamentally resolves these issues. It utilizes the conical structure of a high-strength alloy steel disc. When actuated by hydraulic tensioning tools or torque wrenches, it applies immense and uniform radial pressure simultaneously to the shaft and the coupling hub bore, achieving a keyless, stress concentration-free, fully frictional connection.

2. Structure and Working Principle of Locking Assemblies Diaphragm Couplings

2.1 Basic Structure

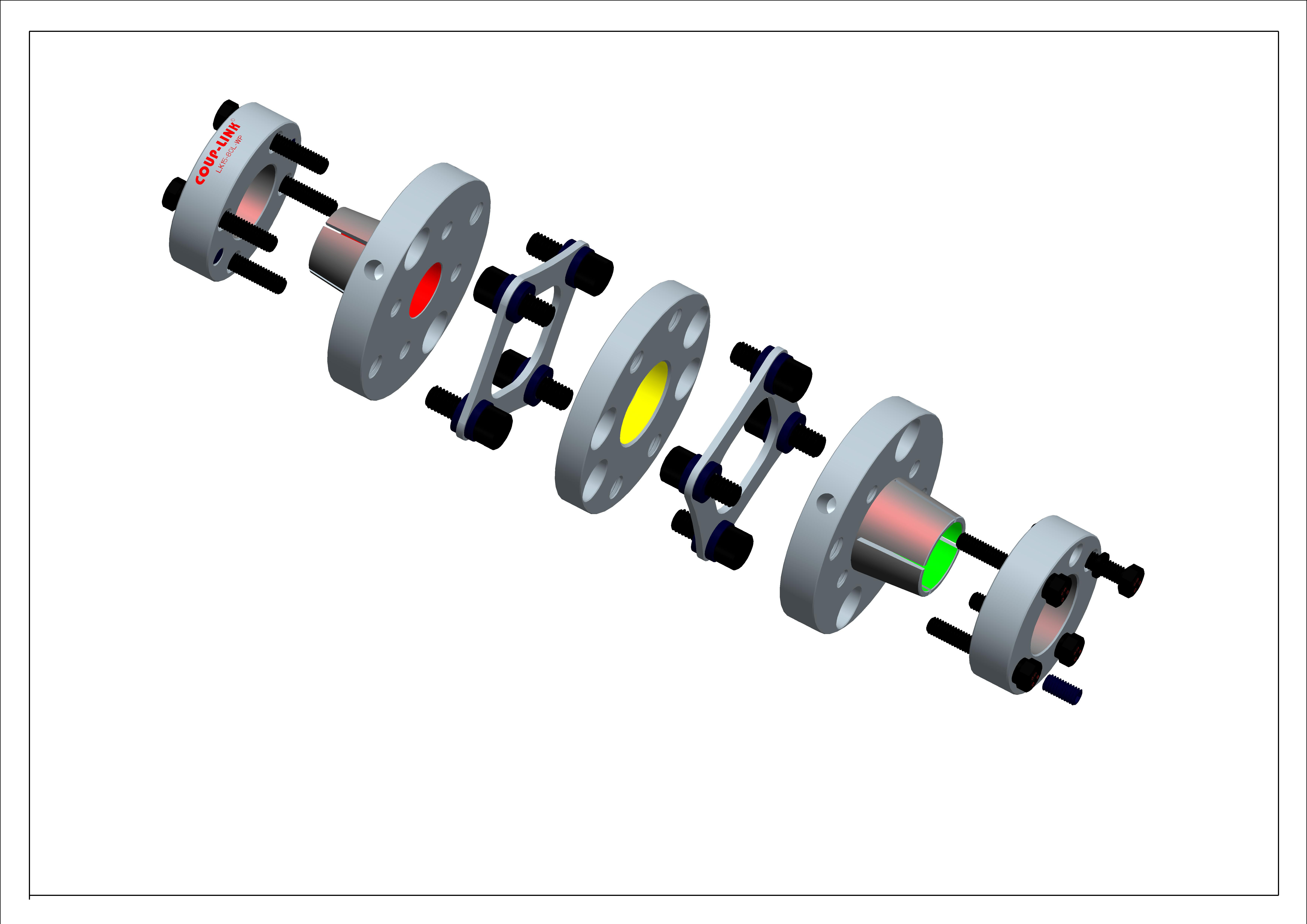

A complete locking assemblies diaphragm coupling consists of three main parts:

Diaphragm Pack(s): The core flexible element for misalignment compensation and torque transmission, comprising multiple layers of high-strength stainless steel laminations.

Spool Piece (Intermediate Section): For multiple diaphragm pack couplings, this connects two diaphragm packs to accommodate larger shaft distances or more complex misalignment compensation needs.

Hub with Integrated Shrink Disc: This is the technological core. The hub is connected to the shaft via the shrink disc, not via traditional keyways or clamping bolts.

2.2 Single vs. Multiple Diaphragm Pack Structures

Single Cardanic Type: Features one diaphragm pack directly connecting the drive and driven shrink disc hubs. Compact, lightweight, with relatively lower misalignment compensation capacity (primarily angular and radial), suitable for applications with high alignment accuracy and short shaft distances.

Double Cardanic Type: Features two diaphragm packs connected by a spool piece. This structure acts like a parallel universal joint, capable of completely isolating misalignment between the input and output sides. It offers superior compensation capacity (handling large radial, angular, and combined misalignments simultaneously), ideal for long drivelines, large units affected by thermal expansion, or where foundation settlement may occur.

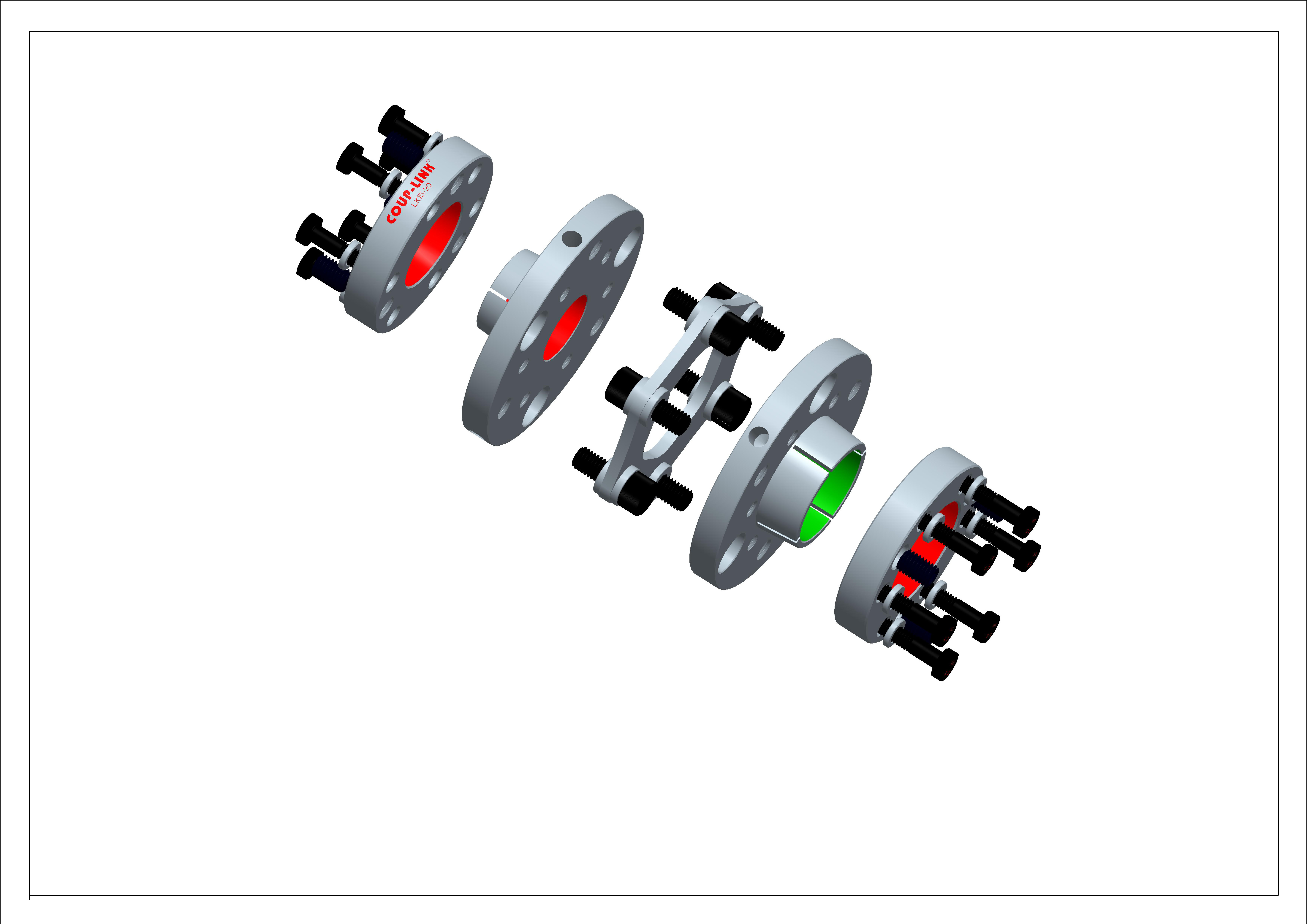

2.3 Working Principle of the Locking Assemblies Coupling Connection

A locking assemblies coupling is an assembly consisting of an inner ring, an outer ring, and tapered clamping rings. Tightening the clamping bolts induces conical interaction, causing the high-strength, elastic inner and outer rings to expand and contract radially:

Outer Ring: Expands radially, creating an interference fit with the coupling hub bore.

Inner Ring: Contracts radially, creating an interference fit with the transmission shaft.

This process generates extremely high surface pressure at the interfaces. The resulting immense frictional force transmits the full operating torque. The torque transmission capacity significantly exceeds that of a keyed connection of comparable size.

3. Core Advantages and Technical Superiority

Stress Concentration-Free Connection:

Completely eliminates the stress concentration effects associated with keyways, avoiding the risks of shaft strength reduction and fatigue fracture caused by keyways. Shaft fatigue life can be increased by over 30%.

Excellent Centering Capability:

The shrink disc self-centers, ensuring perfect concentricity between the shaft and the coupling hub. This eliminates eccentricity errors caused by keyed connections, fundamentally improving dynamic balance quality and facilitating high-speed operation.

High Torque Density and Superior Reliability:

Surface contact pressure is distributed uniformly, providing a theoretical torque transmission capacity 1.5 to 2 times greater than traditional keyed connections. Performance remains unaffected by alternating loads and vibration, with no risk of loosening, ensuring extreme reliability.

Ease of Assembly, Disassembly, and Maintenance:

Simply loosening the clamping bolts releases the shrink disc, allowing the coupling hub to be easily removed from the shaft. This process causes no damage to the shaft or hub, enabling non-destructive repeated assembly and disassembly, which significantly reduces maintenance costs and downtime.

Retention of Inherent Diaphragm Coupling Advantages:

Zero Backlash: Provides precise phasing and synchronization.

High Torsional Stiffness: Ensures high system responsiveness and control accuracy.

Misalignment Compensation: Effectively compensates for axial, radial, and angular misalignment, protecting bearings.

Maintenance-Free Operation: Requires no lubrication and offers good environmental resistance.

4. Application Fields

Locking Assemblies Couplings are deployed in sectors where safety and reliability are paramount due to their exceptional performance:

Energy & Power Generation: Connections between gas turbines/steam turbines and generators/compressors.

Marine & Naval Vessels: Main propulsion systems connecting diesel engines/gas turbines to gearboxes and propeller shafts.

Oil & Gas / Petrochemical: Critical drive applications in pipeline compressors, large pumps, and fans.

High-Speed Applications: High-speed centrifugal compressors, high-speed pumps, flywheel energy storage systems (speeds up to tens of thousands of RPM).

5. Selection, Installation, and Operational Considerations (Key Engineering Practices)

Precise Selection Calculations:

Torque and Speed: Selection must be based on maximum operating torque, peak torque (e.g., starting torque), and maximum operating speed.

Misalignment Capacity: Accurately assess the required axial, radial, and angular misalignment compensation based on system thermal expansion calculations, manufacturing, and installation tolerances. Choose single or multiple diaphragm pack structure accordingly.

System Dynamics Analysis: The coupling's torsional stiffness (K_t) is a key parameter affecting the system's torsional natural frequency. Torsional Vibration Analysis (TVA) is mandatory to avoid operating near critical speeds.

Stringent Installation Protocols:

Alignment Requirements: Although diaphragms compensate for misalignment, initial alignment quality directly determines coupling life and vibration levels. Use laser alignment tools for precision alignment considering both cold and (estimated) hot conditions. Residual misalignment should be strictly controlled within 50% of the manufacturer's allowable values.

Locking Assemblies Coupling Installation:

The contacting shaft section and hub bore must have dimensional accuracy (typically h6/H7 fit) and surface roughness (typically Ra < 1.6 μm).

Absolutely prohibit the use of lubricating oil or anti-corrosion grease. Contact surfaces must be absolutely dry, clean, and free of contaminants.

Use a torque wrench or hydraulic bolt tensioner to tighten the clamping bolts strictly following the manufacturer's specified sequence, angle, and torque values, in a stepped, crosswise, and uniform manner. This is the only way to ensure uniform surface pressure distribution.

Operation and Maintenance Monitoring:

Regular Inspection: Periodically check the torque of the clamping bolts for any relaxation (first re-torque is typically required after 24 hours of operation).

Condition Monitoring: Implementing a vibration monitoring system is recommended to track vibration severity and phase changes on the coupled shaft line in real-time, enabling early detection of worsening alignment or incipient diaphragm fatigue.

Diaphragm Inspection: During major overhauls, perform non-destructive testing (e.g., dye penetrant inspection) on the diaphragm packs to check for micro-cracks.

6. Conclusion and Outlook

Diaphragm couplings utilizing shrink disc connection technology represent the advanced level of high-performance power transmission coupling technology. By combining the excellent misalignment compensation capabilities of diaphragm couplings with the highly reliable shaft-hub connection of shrink discs through a keyless, stress-free method, they are ideally suited for the stringent demands of modern industry for high-speed, heavy-duty, high-precision, long-life, and low-maintenance drive systems.

For the drive systems engineer, a deep understanding of their working principles and strict adherence to their selection and installation protocols are essential for ensuring the safe and stable operation of large critical machinery. Looking forward, advancements in materials science (e.g., composite diaphragms), condition monitoring (integrated sensor smart couplings), and digital twin technology will propel locking assemblies diaphragm couplings towards further lightweighting, intelligence, and predictive maintenance capabilities, providing even more powerful core components for next-generation high-end equipment.

<li id="cucog"></li>