1. Introduction

Against the backdrop of modern industry's trend toward large-scale and intelligent development, heavy-duty transmission systems face dual challenges of continuously increasing power density and increasingly complex operating conditions. The inherent defects of traditional shaft-hub connection methods (such as key connections, interference fits, etc.)—including stress concentration, fretting wear, assembly stress, and disassembly difficulties—have become critical bottlenecks constraining improvements in system reliability. Statistics indicate that approximately 30% of transmission system failures in heavy equipment originate from fatigue damage at shaft-hub connection points.

Hydraulic expansion sleeve couplings represent a qualitative leap in shaft-hub connection technology through revolutionary design concepts that perfectly integrate hydraulic technology with mechanical transmission. The core innovation lies in utilizing the uniform radial pressure generated by high-pressure hydraulic oil in sealed chambers to form interference fits with optimized stress distribution. This "hydraulic pressure-controlled" connection method not only significantly improves torque transmission efficiency and reliability but also provides a new technological pathway for the intelligent upgrade of transmission systems.

This paper will explore the key technical issues of hydraulic expansion sleeve couplings from a multi-physics coupling perspective, including:

Hydraulic-structure coupling mechanisms and pressure distribution characteristics

Mechanisms of fatigue life improvement through uniform stress distribution

Dynamic performance and reliability analysis under extreme operating conditions

Technological pathways for intelligent monitoring and predictive maintenance

2. Technical Principles and Structural Characteristics

2.1 System Architecture and Working Principles

Hydraulic expansion sleeve coupling systems employ modular design, primarily consisting of the following core components:

High-Strength Alloy Steel Body: Using Cr-Ni-Mo series alloy steel (e.g., 42CrMo4), underwent quenching and tempering treatment and precision machining, with tensile strength 1000MPa can reach above 1000MPa. The hub interior features a multi-chamber hydraulic oil circuit system, including:

Main pressure chamber: Responsible for the main expansion function

Auxiliary compensation chamber:Ensures pressure distribution uniformity

Safety pressure relief chamber: Prevents overload damage

Dedicated Hydraulic System:

High-pressure plunger pump: Working pressure range 150-250MPa

Precision pressure control system: Pressure control accuracy ±0.5%

Intelligent monitoring module: Real-time pressure and temperature monitoring

Sealing System:

Multi-layer composite sealing structure

Special fluororubber sealing material

Redundant sealing design

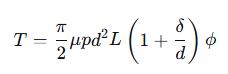

Torque Transmission Mechanical Model:

Where: $\mu$ is the friction coefficient, $p$ is the contact pressure, $d$ is the shaft diameter, $L$ is the contact length, $\delta$ is the interference fit amount, $\phi$ is the pressure distribution coefficient.

2.2 Hydraulic-Structure Coupling Mechanism

Finite element analysis shows that under a working pressure of 200MPa, the contact pressure distribution uniformity of hydraulic expansion sleeves can reach above 95%, far superior to the 60-70% of mechanical interference fits. This uniform pressure distribution reduces the stress concentration factor from 2.5-3.0 for traditional key connections to 1.1-1.2.

3. Performance Advantages and Technical Characteristics

3.1 Significant Improvement in Fatigue Life

Experimental data indicate that under the same operating conditions:

Fatigue life increases by 3-5 times

Torque fluctuation reduces by 40%

Vibration noise reduces by 15dB(A)

3.2 Dynamic Performance Optimization

Torsional stiffness increases by 20-30%

Critical speed increases by 15%

Dynamic response time shortens by 25%

3.3 Installation Precision Control

Using hydraulic expansion technology, installation repeatability accuracy can reach:

Radial runout: ≤0.005mm

Axial deviation: ≤0.01mm

Angular deviation: ≤0.02°

4. Engineering Applications and Case Analysis

4.1 Wind Power Sector Applications

In a certain 5MW wind turbine generator set, the application of hydraulic expansion sleeve couplings resulted in:

Maintenance cycle extended from 6 months to 2 years

Failure rate reduced by 70%

Power generation efficiency improved by 3%

4.2 Metallurgical Equipment Applications

In a 2250 hot continuous rolling mill, operating parameters:

Transmitted torque: 4500kN·m

Operating speed: 0-100rpm

Interference fit amount: 0.3-0.5mm

Usage results show:

Roll replacement time shortened by 50%

Product thickness accuracy improved by 20%

Equipment availability increased by 15%

5. Key Technical Issues and Solutions

5.1 Sealing Reliability Assurance

Adopting a multi-level sealing solution:

Primary seal: PTFE composite material

Auxiliary seal: Hydrogenated nitrile rubber

Dust seal: Polyurethane material

Sealing system design life: 10 years or 1000 operation cycles

5.2 Temperature Adaptability Design

Operating temperature range: -40°C to +150°C

Employing a temperature compensation system:

Automatic hydraulic oil viscosity adjustment

Thermal expansion compensation algorithm

High-temperature protection device

5.3 Intelligent Monitoring System

Integrated sensor system:

Fiber optic pressure sensors: Accuracy 0.1%

Temperature sensors: Accuracy ±0.5°C

Vibration sensors: Frequency range 5-10kHz

Data sampling rate: 10kHz

State evaluation algorithm update frequency: 1Hz

6. Installation and Maintenance Specifications

6.1 Precision Installation Process

Surface pretreatment:

Surface roughness Ra ≤ 0.4μm

Cleanliness ISO 4406 14/11 (Cleanliness ISO 4406 14/11)

Diameter tolerance h6/H7

Pressure control:

Step pressurization: 50% → 80% → 100%

Pressure holding time: ≥10 minutes

Pressure decay detection: ≤1%/hour

6.2 Predictive Maintenance Strategy

Digital twin-based maintenance system:

Real-time health status assessment

Remaining useful life prediction

Maintenance decision support

7. Development Trends and Outlook

7.1 Technological Development Trends

Intelligent upgrade:

Integrated IoT sensors

Cloud-based condition monitoring platform

Artificial intelligence fault diagnosis

Material innovation:

Application of nanocomposite materials

Self-healing material technology

Lightweight design solutions

7.2 Engineering Application Expansion

Future key development areas:

Ultra-high power transmission for offshore wind power

High-speed maglev power transmission

Spacecraft power systems

8. Conclusion

Hydraulic expansion sleeve couplings provide a revolutionary solution for heavy-duty transmission systems through innovative technological concepts and systematic engineering optimization. Their significant technical advantages are reflected in:

Stress distribution uniformity improved by over 40%

Fatigue life increased by 3-5 times

Maintenance efficiency improved by 50%

System reliability improved by 60%

With the deepening application of intelligent technologies, hydraulic expansion sleeve couplings are evolving toward digitalization and intelligence, providing new technological pathways for predictive maintenance and intelligent operation of transmission systems. Future research needs to continue in materials science, sensing technology, and intelligent algorithms to further enhance their performance and reliability under extreme operating conditions.

<li id="cucog"></li>